Duplex alloys – an ideal compromise

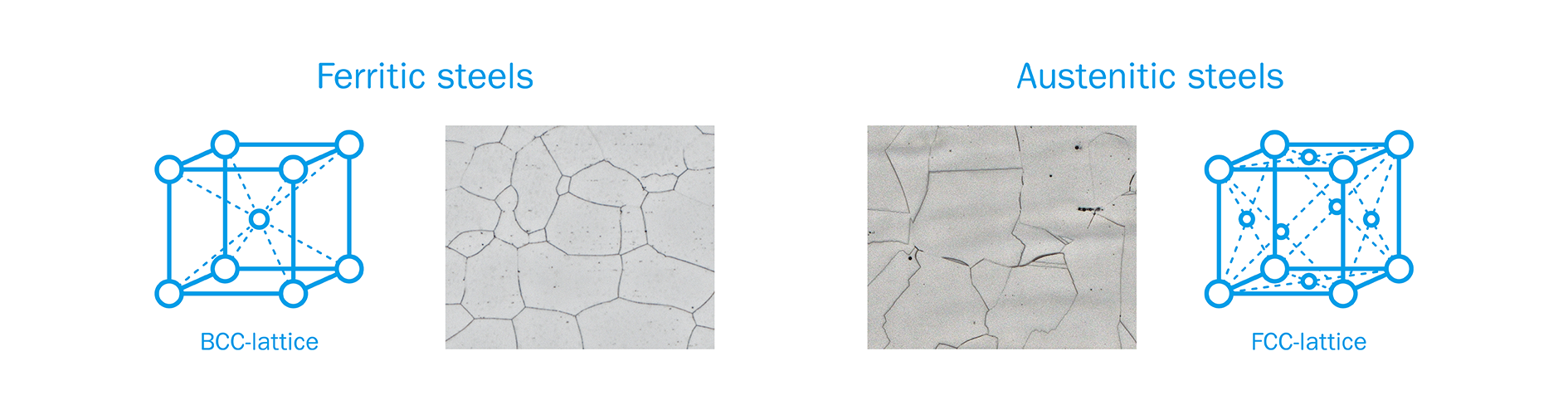

At a microscopic level, the atoms in all steel and iron alloys mainly arrange themselves in one of three ways: ferrite, austenite and martensite. Ferrite is based on a crystal structure in the shape of a cube with an atom at each corner and one in the centre of its body (called body centered cubic). Austenite is also cubic but has additional atoms on each one of the cube’s six faces (face centered cubic). Martensite has a distorted crystal structure formed by diffusionless transformation either during fast cooling or due to introduction of mechanical stresses in some austenitic structures.These microstructures, or phases, have a big impact on the properties of the material. Broadly speaking, ferritic stainless steels are relatively low cost, austenitic stainless steels have excellent corrosion resistance and martensitic stainless steels are very hard and strong but brittle.

The achievement of duplex stainless steel is that it combines the best properties of both ferrite and austenite. The result is a range of alloys that provide corrosion resistance, cost competitiveness and high strength. At Outokumpu, we’ve developed duplex grades as a whole range of alloys with various alloying elements that bring specific properties for many different applications.